INDUSTRY 4.0

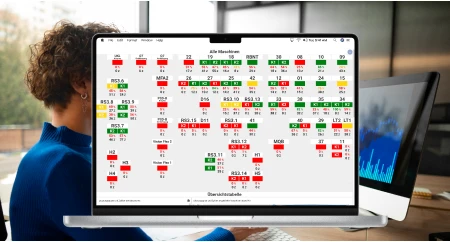

Real-Time production monitoring for automotive supplier by süc//dacor GmbH using ThingsBoard

süc//dacor GmbH is more than a regional internet provider — it is a forward-thinking technology partner for businesses navigating the digital era. Headquartered in Coburg, Germany, the company combines over 25 years of experience in telecommunications with a strong focus on IoT, smart infrastructure, and digital services. süc//dacor is a leading force in deploying LoRaWAN networks and intelligent solutions, helping enterprises shift from traditional automation to real-time, data-driven operations.

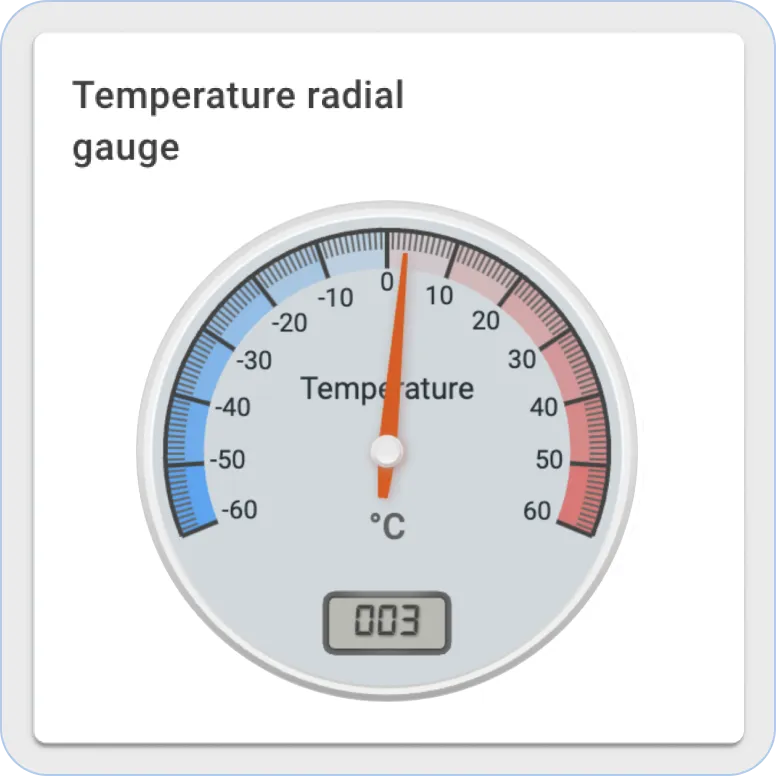

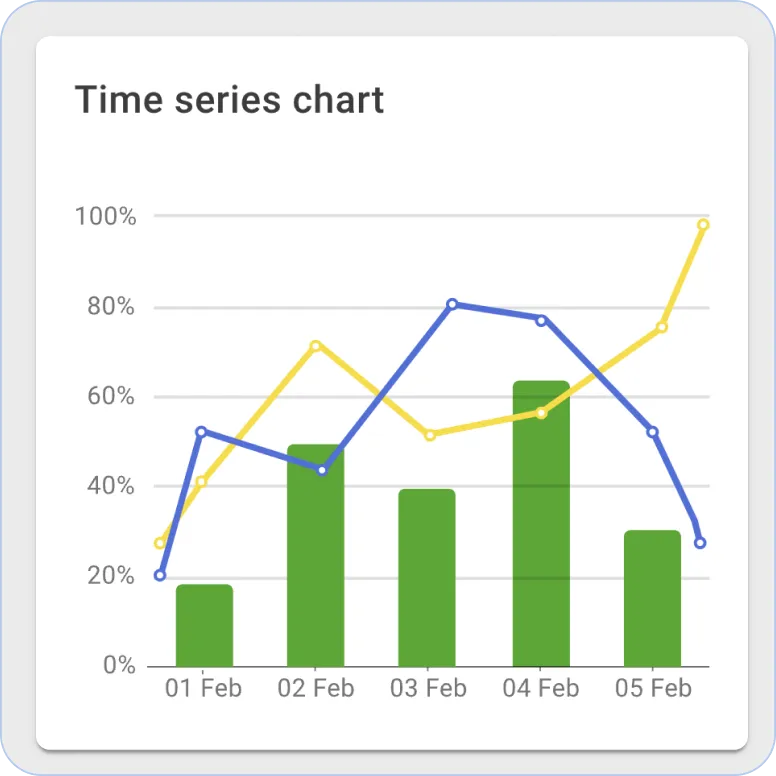

The company offers end-to-end IoT implementation — from device integration and data acquisition to visualization through platforms like ThingsBoard. Their solutions have already proven effective in industrial monitoring, smart energy, and infrastructure projects. With a unique blend of technical expertise and business-driven thinking, süc//dacor empowers its clients to increase efficiency, reduce operational costs, and accelerate their journey toward digital transformation.