Introduction

For solar farms, dirty panels can mean thousands of dollars of lost revenue annually. Panels washed too early or too late – are costs that make up a serious portion of the power plant’s profitability.

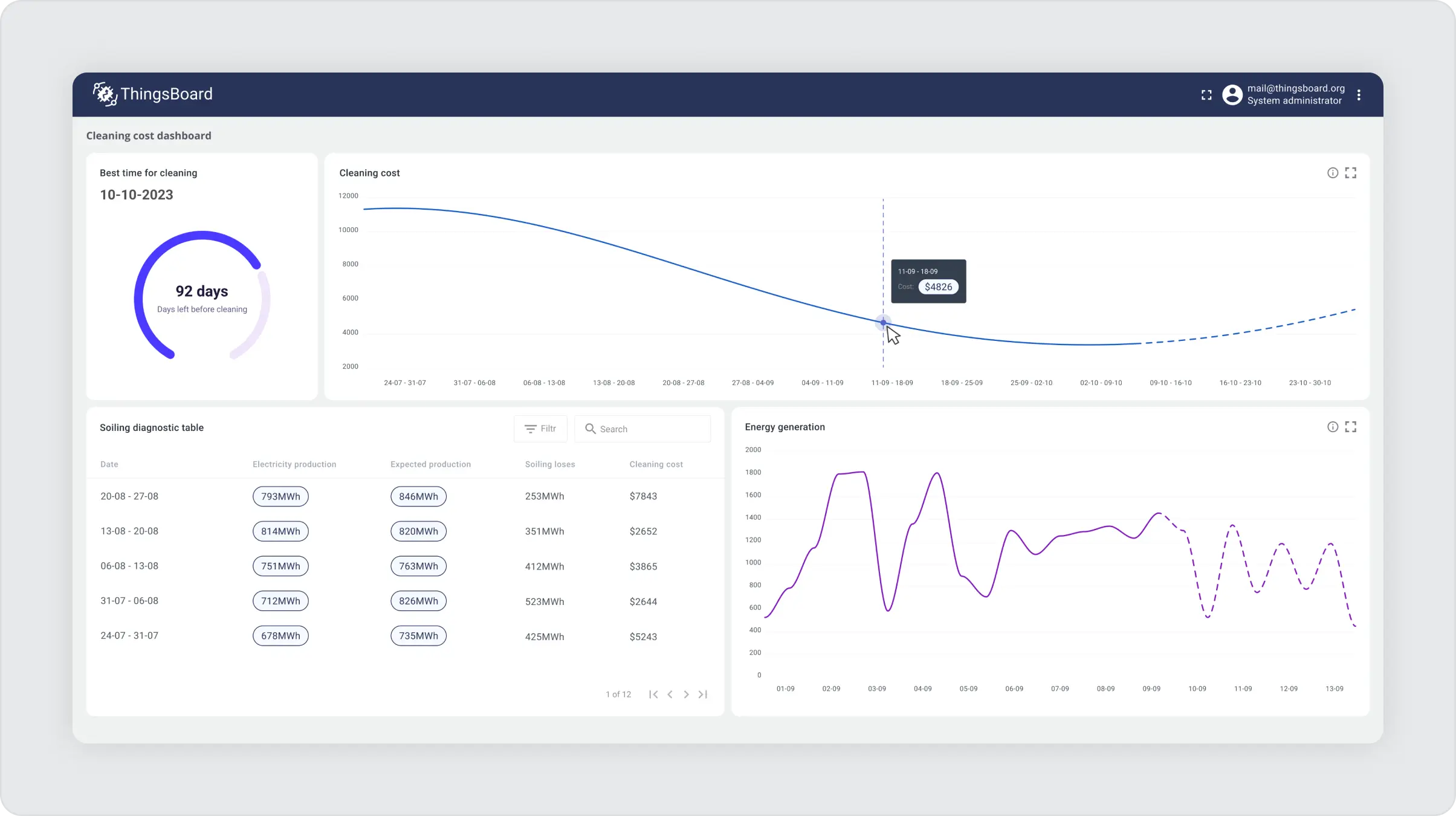

In one of our cases, we worked with a Spanish company, a producer of electricity. They owned a solar power plant with a capacity of 10 MW. They will produce about $260,000 worth of energy per month in ideal conditions. However, the company lost over a fifth of its energy due to soiling problems. In turn, the cost of the cleaning cycle was $50,000. Calculating the losses, it was clear that cleaning on a fixed schedule was showing poor results.

To get the best possible results, you need to be sure of 3 steps:

- We have to find the energy losses

- We need to know the forecast for electricity losses.

- You need to find the best time for the cleaning cycle.

The key to solving all these questions is advanced analytics. A correctly configured system, like an expert, automatically decides what to do based on real-time and forecasted data and can manage the entire cleaning cycle, from collecting information to turning on the irrigation system or calling a group of cleaners without outside intervention.

Using IoT sensors to track real-time solar generation data, our solution provides actionable intelligence to optimize your cleaning schedule. Here’s how it works:

- Sensors are installed to monitor energy production from individual panels. This allows precise tracking of solar output over time.

- Advanced analytics calculate expected energy generation based on weather conditions and other variables. The difference between expected and available energy generation is considered energy loss.

- Our algorithm evaluates the cost of cleaning against potential energy savings. It forecasts lost revenue accrued each day panels remain dirty.

- When the value of regained energy outweighs cleaning expenses, the system automatically alerts owners it’s time to wash or turn off/on the cleaning system.

- Targeted cleanings restore generation at the optimal moment. You have the opportunity to adjust the cleaning schedule based on the economic feasibility of your decisions.

Customers using our solar IoT solution have increased generation by 5-15% while reducing cleaning costs by up to 40%. Solar assets stay active at peak efficiency by timing cleanings precisely when needed.

Effective Solar Panel Cleaning. How to optimize Solar Panel cleaning schedule

Our approach to solving this problem is based on Soiling cost calculation.

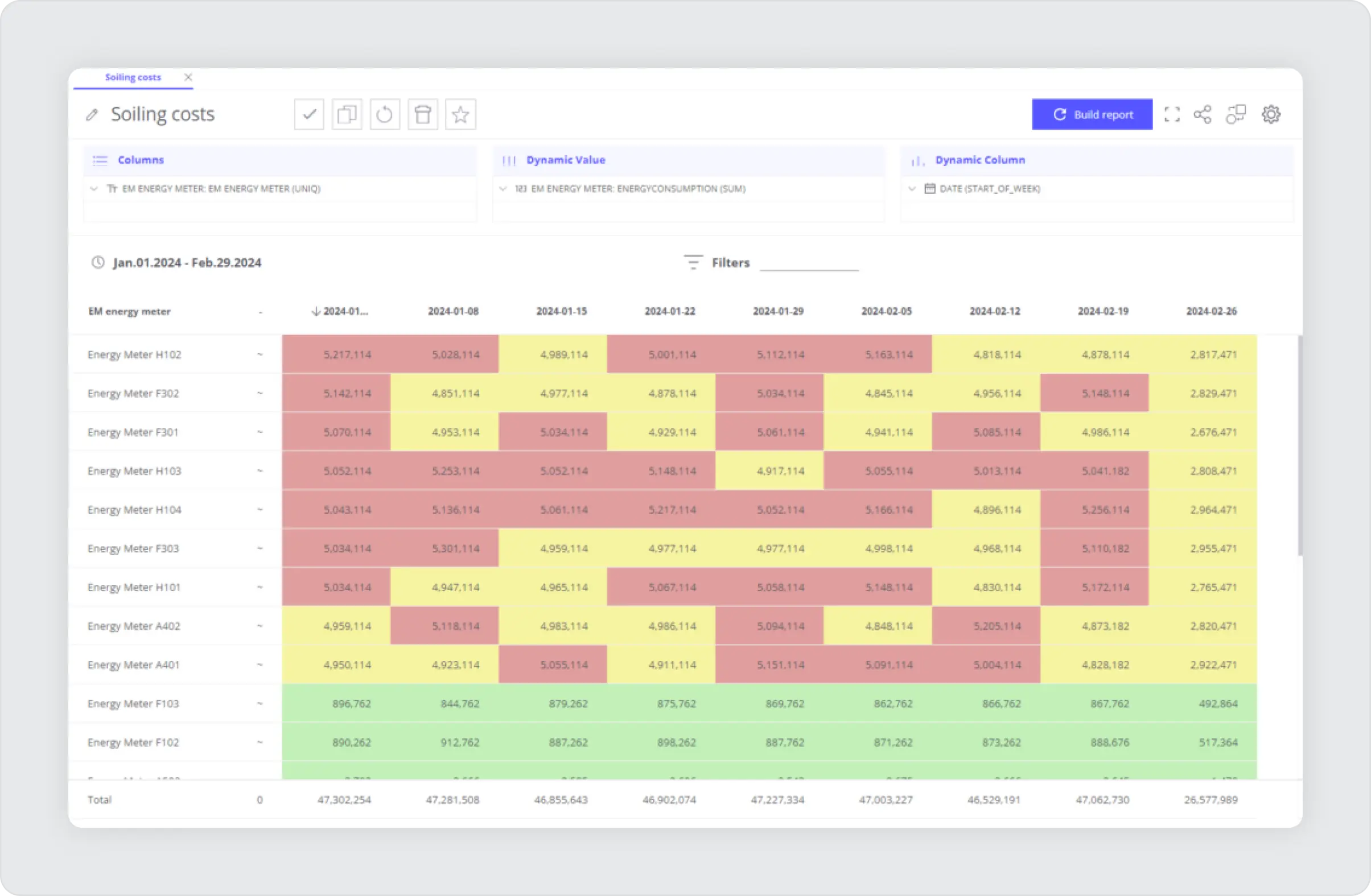

Soiling costs are the losses you will incur if you clean your station on this day. This indicator consists of the cost of cleaning for a 10 MW plant, which is approximately $50,000, the sum of all losses due to pollution, and all this is divided by the number of days since the last cleaning.

The indicator drops – good because our costs are decreasing. The indicator starts to rise – you need to wash the panels because the current costs are at their lowest point and then will constantly grow, and that is exactly the point when cleaning is economically feasible. As we can see in the table, in the dry period, when the loss indicators are only growing, the 5th week is the best time to carry out the cleaning cycle because compared to cleaning in any other week, the price is the lowest.

That is why we need to set up an IoT system with advanced analytics to optimize the cleaning schedule based on the historical data from the solar plant, the production forecast, and the metrics we explained in this section.

Summary

Solar power plants have many advantages, but due to their novelty, they also have many disadvantages. One of the most common is overspending based on pollution. This is a problem that cannot be eliminated, so the goal – is to minimize losses. Using IoT technologies and advanced analytics, you can easily monitor and wash solar panels at exactly the point in time when cleaning is economically feasible.

Analytics, IoT, and machine learning provide insights, risk forecasts, and data-driven decisions for better business performance. Embracing these ensures competitiveness and risk mitigation. Also, in the future, we plan to tell you how to improve the efficiency of the power plant by finding anomalies in the solar panels and parts of the power plant, such as the inverter or the battery. In our digital age, advanced analytics are the way to simplify and boost complex problem-solving!